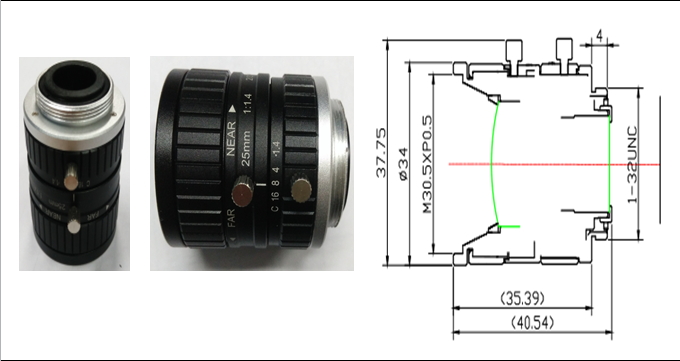

Product Name: 1080P 25mm 2/3’’ Image Format Industrial-use Lenses

Product advantage:

1, Variable Aperture LensFromLarge aperture F2.0 to Smallest F22 (creat good depth of Focus)

2,Multi-layer coating, with higher transmittance and effective suppression of stray light

All glass + metal structure design, good high and low temperature resistance

3, Applied For 2/3" megapixel Industrial Securitycamera with C-Mount

4, 25mm Camera Lens with C mount Widely used in Industrial Quality control cameras, Machine vision cameras, Industry cameras for inspection and imaging processing, scientific Research, Industrial robotics, Ruggedized cameras for security and defense, Industrial Photography Optics Industrial Surveillance and Security etc

Product technical Specification of 25mm CMount Lens

|

Product Model |

NWA-23-3MP-25mm |

|

Image Cmos Sensor Format |

2/3’’ |

|

Photo Resolution |

3MP |

|

Focal Length |

25mm |

|

Aperture |

F1.4~C |

|

FOV(D×H×V) 2/3 inch cmos |

D24.7°/ H19.9°/ V15° |

|

FOV(D×H×V) 1/2 inch cmos |

D18.1°/ H14.6°/ V11° |

|

TV Distortion 2/3 inch cmos |

-0.27% y=5.5mm |

|

TV Distortion 1/2 inch cmos |

-0.10% y=4mm |

|

Focusing Range MOD (Minimum Object Distance) |

0.15m ~ ∞ |

|

Flange Distance |

17.526㎜ |

|

Operation Mode- Focus |

Manual with Lock |

|

Operation Mode –Iris |

Manual Variable |

|

Operation Mode-zoom |

Fixed |

|

TTL |

39.39mm |

|

Mount type |

C mount |

|

Filter Thread |

M30.5×P0.5 |

|

External Dimensions(mm): |

∅34*L40.5mm |

|

Structure |

Full Glasses Lenses+Metal Barrel |

|

Working temperature |

-10℃~+50℃ |

|

Storage Temperature Range |

-20℃~+60℃ |

25mm C Mount Lens Industrial cameras applications

1. Industrial field: For example, when developing metal materials and resin materials, it is used to observe the direction and state of internal cracks when the material is impacted. It can be used to analyze the structure of the material when the material is destroyed, and the industrial online inspection of electronic products.

2. In the printing process of the packaging and label industry, subtle defects in high-speed printing can be detected in real time, which is convenient for taking measures to reduce losses. Common defects such as scratches, dust, missing prints, ink marks, wrinkles, etc. will be detected. Industrial cameras can be used for machine vision inspection to find printing problems, which can provide valuable information for production so that they can be taken during the production process. Measures to reduce losses.

3. In the intelligent transportation industry: speeding snapshots, red light electronic police, highway intersections, buckle tolls and other transportation industries have also made good use, and the performance of capturing high-speed moving objects is very good.

4. Machine vision, industrial monitoring and inspection, material inspection, PCB and SMT inspection, printing and packaging, textile inspection, four-wheel positioning, solar panel inspection, robot automation, motion dynamic monitoring, robot navigation and recognition

5. Factory production automation, especially for parts identification, sorting and inspection, measurement applications, logistics and quality assurance, pharmaceutical monitoring, food processing, inspection of continuous mesh materials, such as printing inspection, microscope application, product defect detection ( Video microscope), defect detection (machine vision system detection), size measurement (one-button measuring instrument and other equipment), face recognition, security,

6. Semiconductors, mechanical parts, scientific research image processing, electronics and automobiles, medical, military manufacturing,Mechanical parts measurement, plastic parts measurement, glass and pharmaceutical container measurement, electronic component measurement, etc.